David Morgan review: Simes IP System

Since its launch at Light + Building last year, the IP System from Simes has been causing a buzz among the lighting design community. Here, David Morgan takes a closer look at the range to see what all the fuss is about.

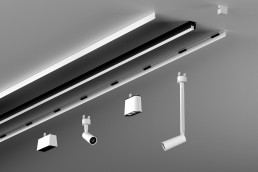

It is exciting and unusual to review a lighting system that combines a unique combination of features. The IP system from Simes is such a system. It combines an exterior rated silicone encapsulated diffuse linear lighting system with an exterior rated track system for projectors and accent lighting luminaires that can be added or removed along the length of the system.

Simes is based in Franciacorta, in the Brescia region of Italy north of Milan. The current firm was founded in 1973, although the origins of the company date back to 1957, when Edigio Botti started a metals machining company at his home. The company expanded and, in 1972, purchasing the Bruno Magnani company that specialised in exterior lighting. The company name was changed to Simes a year later and the first new product launched was a redesigned die cast bulkhead luminaire that was offered in a range of bright colours.

Under the management of Edigio Botti’s son, Roberto Botti, who has run the firm since 1990, the company has continued to grow and now employs 120 people. With sales distribution in more than 60 countries, around 70% of sales are outside Italy. All of the company’s components are designed in-house, and most are sourced from trusted local suppliers in the region.

The company has worked with a variety of high-profile designers to create new products since 1986. In 2016, I reviewed for arc magazine the innovative Simes Ghost concrete integrated range, designed by Marc Sadler.

The latest development from Simes is the IP System, which was unveiled at Light + Building in 2022 and has received an enthusiastic response from the lighting design community.

The original concept for an exterior IP rated track system was developed by Roberto Botti over many years. The eureka moment was apparently revealed in a dream when he realised the opal silicone used to encapsulate exterior linear lighting systems could also be used as a gasket in a waterproof track system. The Simes in-house design team got to work and quickly developed a working prototype to prove the design approach.

At the heart of the IP System is a custom flexible LED tape fitted with tight pitch LEDs. This produces the light output for the linear diffuse lighting system branded as the Highlighter by Simes. Running either side of the LED circuit are two additional copper conductor strips, which are used to power the plug-in projectors and other luminaires. The side conductors have a separate power supply from the central LED strip enabling each circuit to be independently controlled. A complex dual material silicone extrusion provides the diffusion for the LEDs and aims to seal the tape from water ingress.

The electrical connections between the plug-in luminaires and the conductive copper strips are made with sharp pins that pierce through the silicone diffuser without leaving space for water ingress. The silicone extrusion is housed in an aluminium extrusion, which gives the system it’s strength and rigidity. The plug-in luminaires snap onto the aluminium extrusion with stainless steel clips. Extruded aluminium side panels are then clipped onto the body extrusion to give a clean, finished appearance.

The Highlighter is available in both surface mount and ceiling recessed versions with lengths up to four metres. The system can be cut to a 50mm module, but this has to be done by Simes during production and cannot be undertaken on site. The Highlighter without any additional snap-in luminaires is rated at IP65. When the snap-in luminaires are first added, the IP rating remains at IP65 but once these luminaires are removed and then moved to a new position the rating for the whole system drops to IP54. I assume that the puncture holes in the silicone extrusion do not completely heal and may provide a water ingress path to the LED tape.

The snap-in luminaire installation is a little more complicated than I expected and requires the use of a patented, moulded jig to ensure that the contact pins pierce the silicone extrusion perfectly perpendicular to the surface. To protect the contact pins and ensure they are not distorted, a specially designed moulded cover is provided for each snap-in luminaire. Removing the luminaires from the track is also slightly difficult as the stainless-steel clips are an aggressive fit yet seem to allow the projectors in particular, to wobble slightly. It helps to remove the side panels before removing and repositioning the snap-in luminaires. For the ceiling recessed version this would mean removing the system from the ceiling before moving any of the snap in luminaires.

The sample I was given to test worked well with the caveat that there is a knack to getting the snap-in luminaires to make contact through the silicone extrusion. The lit effect from both the linear Highlighter and the snap-in luminaires was good with attractive, clean distributions.

The maximum wattage for all the snap-in luminaires per circuit is 60W, which may be limiting in some situations.

The range of plug-in luminaires includes two sizes of adjustable projectors: 5.4W and 8.6W. The larger size incorporates a zoom lens. Both sizes can be aimed and locked with grub screws. Snoot versions are also available.

In addition to the adjustable projectors, the IP System includes two styles of fixed downlight. A rectilinear wide flood type design in two sizes rated at 4.2W and 8.4W, and a radius end type with narrower optics rated at 4.2W.

A cylindrical 4.2W pendant available in flood and wide-flood distributions completes the current range of add-on luminaires.

The design of the system is well-detailed from an appearance point of view. However, construction of the luminaires involves the use of hard setting resins, which will make servicing, reuse, or recycling of the die cast and machined aluminium components problematic at the end of life, so the system does not fit into a circular economy model particularly well. It will be interesting to see how the system copes with high levels of heat and moisture in challenging environments over the long term.

The IP System is another example of the innovative and quite daring Simes design approach to luminaire development and the initial positive reaction from specifiers indicates that it will prove to be a commercial success.