[d]arc dialogues: making the most of manufacturer relationships

“Meeting manufacturers is like bringing new oxygen to our creative brain: the technology is moving forward so fast… which can only be overcome by continuous meetings with leading manufacturers.”

In the ever-evolving world of lighting design, staying abreast of the latest innovations and maintaining strong connections with manufacturers is crucial. We spoke to Arianna Ghezzi of Lighting Design International to explore how meetings with manufacturers, such as those at [d]arc sessions, play an integral role in the design process. Ghezzi shares valuable insights on fostering productive relationships that benefit both designers and suppliers, as well as what influences a specifier’s product selection.

What value do manufacturer meetings, like those at [d]arc sessions, bring to your design process?

Meeting manufacturers is like bringing new oxygen to our creative brain: the technology is moving forward so fast, and being always updated regarding new products, it’s a challenge which can only be overcome by continuous meetings with leading manufacturers.

The speed-dating format is unique. How does it compare to more traditional ways of discovering new products or brands?

The [d]arc sessions format suits a designer’s busy schedule: in a couple of days, multiple meetings are scheduled, and the quick speed-dating format allows for keeping the attention high and focused. During the [d]arc sessions, there is also a chance of discovering manufacturers which are local to the event’s location, so it’s convenient for getting a broader market knowledge.

What do you look for in a first interaction with a manufacturer? What makes a lasting impression?

Deep technical knowledge from the manufacturer representative, availability to provide customisation to standard products and proactiveness in assisting us as specifiers. The biggest added value is for the suppliers to be reachable, as we have millions of questions, so be ready to know your products inside out.

Have you ever discovered a product or company through one of these short meetings that ended up playing a key role in a project?

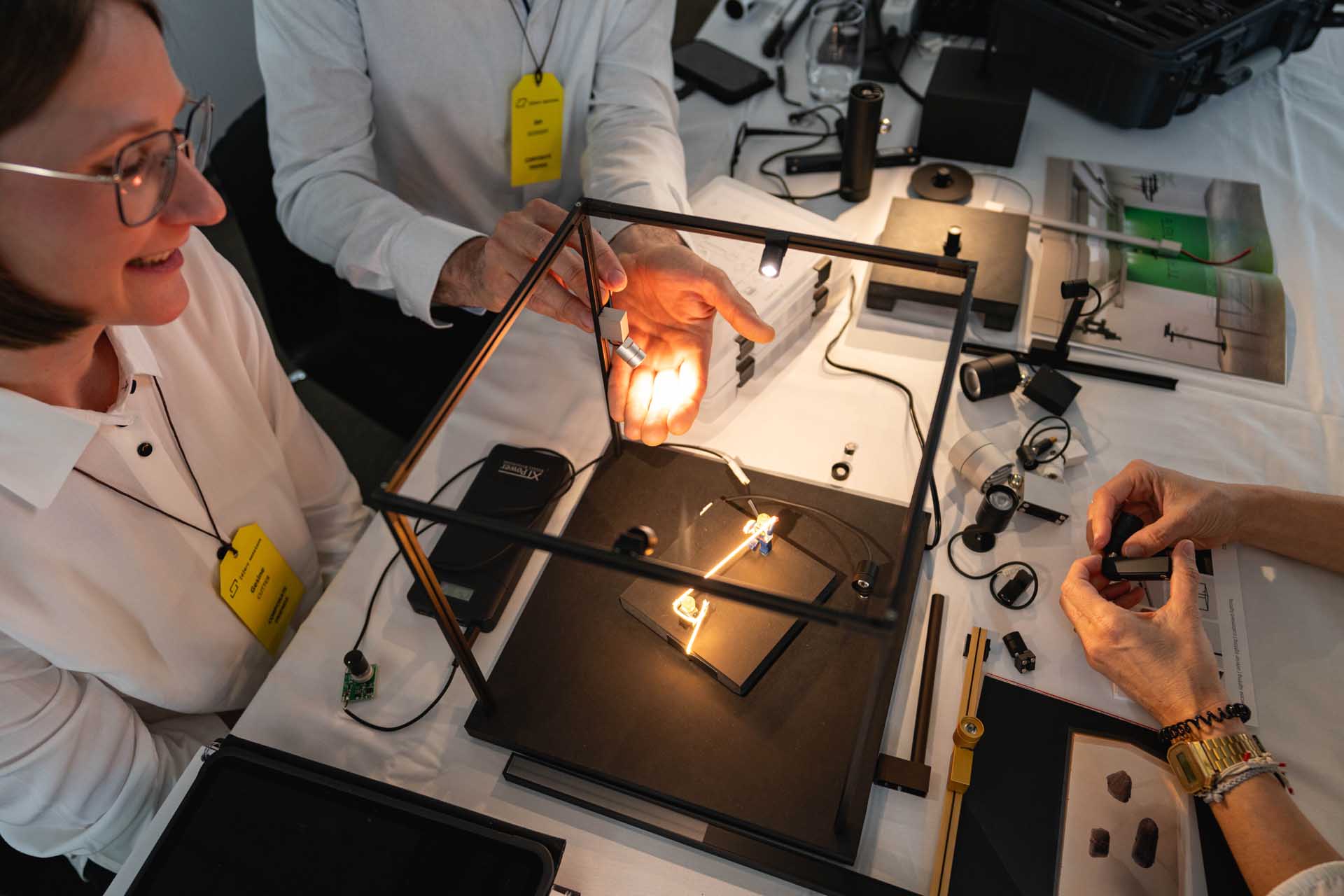

Absolutely – many times! One example is discovering Tekna’s lanterns, particularly the versions wrapped in leather. I was impressed by the craftsmanship and immediately wanted to incorporate that level of detail and materiality into a project. During the sessions I attended, I was also struck by the level of miniaturisation our industry is achieving. The mini joinery lights from Corporate Friends and DGA stood out in particular. I’ve since specified DGA’s Nano Tini I in several projects – it’s a versatile fitting that works beautifully across both residential and hospitality settings.

What’s so valuable about [d]arc sessions is the exposure to such a wide range of products – from interior and exterior to decorative – all in one place. It creates a real opportunity for immediate application, bringing fresh ideas and innovative options into our lighting schemes. It’s also worth mentioning that these meetings often provide a chance to reconnect with manufacturers we may have lost touch with, which can be just as valuable as discovering new ones.

How important is it for a manufacturer to understand your design vision and project needs? What helps build that mutual understanding early on?

It is paramount for the manufacturers to understand the project programme, the budget and the requirements in terms of our design aspirations and understanding which ranges of products we are looking for – this makes our understanding of their offerings as easy as possible. Sometimes, as specifiers, we might feel overwhelmed by the offering and being able to just talk to the manufacturers through our requirements, without endless scrolling of the catalogues online, is a plus.

What kind of technical or creative input do you most value from suppliers during a project?

From a technical perspective, we value clear data, delivered outputs, available ltd files and intuitive list performances. Additionally, having these available digitally or in some other easily reachable format is important too. It’s paramount to be able to review samples, and the quick availability of those is very important. From a creative point of view, it is valuable when manufacturers share how the products might have been used previously, especially if in an alternative way or out of the out-of-the-box way. Manufacturers not only need to stimulate us as designers with new products, but also show present images where we appreciate products being installed in real projects.

Do you think manufacturers are adapting well to changing design priorities, like sustainability, modularity, or reuse?

There’s certainly a strong and growing effort across the industry, with increasing attention being paid to sustainability, reusability, and the development of modular or interchangeable fixtures. The latter is particularly valuable – not only from a sustainability perspective, but also as a highly effective design tool. We all know that conditions on site often differ from initial expectations, and having the flexibility to swap out modules, lenses, or optics provides a level of adaptability that is crucial in real-world applications. As specifiers, we should begin to prioritise manufacturers who demonstrate a genuine commitment to sustainability, so that together we can move towards a more environmentally conscious and responsible approach to lighting our projects beautifully and intelligently.

How do you balance innovation and reliability when specifying products you may not have used before?

Striking the right balance begins with a thorough review of the product’s technical specifications. However, this must be followed by a hands-on evaluation. Examining a physical sample is essential to assess the quality of assembly, the light output, the colour consistency, and whether the beam aligns with the manufacturer’s claims. Dimming performance is another key aspect we always test.

We also consider the robustness of the fixture – how well it’s finished, whether it feels durable, and whether accessories or modular components can be added or removed without compromising its integrity. Beyond the product itself, it’s important to understand how it has performed in previous installations, including reliability over time, warranty coverage, and the manufacturer’s approach to repairs or replacements if needed.

Practicalities also play a significant role. We check the availability of accessories, lead times for delivery, and whether the product fits seamlessly within the project timeline. Packaging is another indicator, not only in terms of sustainability but also how well it protects the product. Lastly, we review the clarity and usability of the installation manual, as this can greatly impact the efficiency of on-site work by the electrical contractor.

Are there common pitfalls you see in how manufacturers approach lighting designers, things you wish they’d do differently?

One of the most common pitfalls is a lack of understanding of the type of projects a particular consultancy typically works on. I would strongly encourage manufacturers to familiarise themselves with our portfolio before reaching out, so they can offer products that are genuinely relevant to our work. We’re sometimes approached with ranges that don’t align with our design focus or technical requirements, which makes the conversation less productive from the outset.

Another improvement would be in how new products are introduced. Rather than relying solely on catalogues or email announcements, it’s far more valuable for us to receive a working sample for review. While we understand manufacturers want to generate early interest, our priority is to evaluate the actual product – how it performs, how it feels, and whether it meets our standards.

It can be quite frustrating when we’re excited by a new product but can’t specify it because it’s not yet in full production or stock. Having tangible, review-ready samples available early on would go a long way in helping us make informed, timely decisions and ultimately benefit both sides.

What do you think lighting designers could do better to foster strong supplier relationships?

As lighting designers, we can play a more active role in strengthening supplier relationships by clearly communicating our evolving needs – what types of fittings we specify most often, and what gaps we’re noticing in the current market offering. If there’s something we feel is missing, it’s important to share that insight. These conversations can happen through meetings or informally, during networking opportunities, but they’re essential for driving product development in the right direction.

Ultimately, manufacturers are the bridges between our creative vision and the project execution: we as designers also have a responsibility to keep communication channels very open to make sure we have a strong relationship in place, for the best outcome of the project. Working closely with manufacturers means also collaborating on new or bespoke fittings that might have use in the broader market, we’re contributing to the ongoing innovation of the lighting industry, which benefits everyone.Top of FormBottom of Form

How much influence do manufacturer relationships have on the early concept stages of your designs, or are they more relevant further down the line?

I would say the relationship is more relevant further down the line, although there have been occasions where I got so excited about a new product – and if it was the right project – thinking about possible uses during the concept stage, especially if the product was creating a special lighting effect or a feature of sorts.

When it comes to product sustainability or lifecycle thinking, how transparent are manufacturers nowadays, in your experience?

My experience is that manufacturers are being more transparent and share more information these days, of course, as designers, we also appreciate that some information and data might be very challenging or expensive to get hold of. What is recognised is also the effort towards sustainability and the gathering of the lifecycle information and data. There has also been a huge effort from manufacturers to run CPDs or share their knowledge on regulation, or make sure designers are heard and supported; this should be much appreciated as a joint effort towards more sustainable lighting design.

Are there any changes you’d like to see in how designers and suppliers collaborate in the future?

I’d like to see the relationships between lighting design and manufacturers grow stronger. Manufacturers can be a valuable support to us as designers, and designers shouldn’t hesitate to rely on manufacturers more for help. It would be particularly helpful if manufacturers shared more insight from past projects, such as lessons learnt, challenges encountered during supply or procurement, and how these were resolved. This kind of transparency helps us all improve and better anticipate potential issues.

From a designer’s perspective, we want our specifications to be protected, and by working closely with the manufacturers, we can find a way to make sure this happens. It would be interesting to create more opportunities to have open dialogues about what we need as specifiers, what we feel the market is missing. These conversations could help shape the next wave of innovation in lighting, driven by real project needs and creative ambition.

What advice would you give to a young lighting designer attending their first supplier meeting or trade event?

Touch everything! This aside, don’t be afraid to ask lots of questions, take lots of pictures and make your mental catalogue of fittings and manufacturers that you have found interesting. Plus, they should create and nurture this amazing connection we should have between specifiers and manufacturers, working closely together to deliver amazing projects.

If you’re interested in finding out more about what [d]arc sessions does then follow the link www.darcsessions.com or alternatively manufacturers can contact j.pennington@mondiale.co.uk for any queries or further. information

www.lightingdesigninternational.com