David Morgan: Panel Show

David Morgan runs David Morgan Associates, a London-based international design consultancy specialising in luminaire design and development and is also MD of Radiant Architectural Lighting.

Side lit prismatic lighting panels are not usually the most innovative product area in the lighting world, but an Italian company has taken this product type to a new level of lit effect and performance, so I wanted to learn more about the products and the company behind them.

Folio Lighting, based in Brescia, was formed from a group of companies that was started in 1986 by Marco Maitini, who was active in the development of the aluminium extrusion industry. He introduced the Porsa extruded aluminium modular furniture system into Italy. The system, originally designed in Denmark, was developed and marketed for use in a wide range of furniture and other applications.

In 1992, Cifralluminio, the second company in the group was launched by Marco Maitini and Silvia Salamone to further utilise aluminium extrusions for use in interior and exterior signage, advertising banners and other similar applications. They are still active in the company as President and CFO. At this point, lighting technology was added to the company’s capabilities in order to create custom designed, back-lit luminous signs.

The final stage in the development of the Group occurred in 2009 when Roberto Maitini, son of Marco, launched Folio to focus on the lighting market. A US office was opened in New York in 2018 to service the North American market, with sales teams on both East and West coasts. The company employs around 50 people in Brescia and sells in developed markets around the world, working closely with lighting specifiers, architects, and interior designers.

The company produces all of its products in house, has a strong ESG policy, and is Ecovadis Platinum rated.

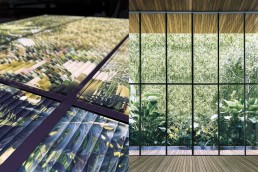

Folio specialises in the production of side-lit luminous surfaces (as they prefer to call them rather than panels) for use in high-end retail, hospitality, and many other applications. These illuminated surfaces are utilised as back lights for walls and ceilings, behind light-transmissive materials including onyx and marble, or used behind perforated metals.

In addition to the plain opal panels, the Folio product range features a variety of panels combined with surface materials, including marble, printed layers, textiles, glass mosaics, and even opal-acrylic with routed surface details.

The panels can be curved into custom profiles and can also integrate cut-outs for downlights or track mounted or individual projectors to create complete pendant luminaires for use in retail lighting applications

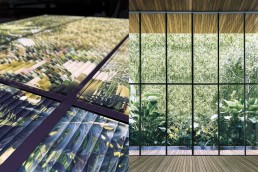

It is understood that the proprietary micro-engraving technique that Folio uses to create the acrylic prismatic panels achieves an industry-leading 97% uniformity for luminance, and also colour point accuracy. They are able to achieve this performance on their maximum size surfaces of up to two by three-metres. This micro-engraving process is driven by a sophisticated mathematical algorithm that, according to the size and shape of the individual prisms that make up the luminous surface, optimises light transmission. The company is continuing to develop this process to achieve an even higher performance in the future. Panels are available in a range of thicknesses from seven, nine, 12 and 19mm.

The LED light engines used to power the surfaces are designed and produced in-house using tightly binned LEDs from Nichia to ensure high efficiency and excellent colour uniformity. The maximum lumen output is around 5,000/sqm, with a power consumption of around 100W/sqm, depending on the colour temperature and CRI.

A wide range of colour temperature LEDs can be used for the light engines, ranging from 2000K up to 5700K. Tuneable white, RGBW as well as full spectrum and Vitasolis light engines are also available.

One of the latest innovations from Folio is its Fluted product, whereby the illuminated surfaces are combined with an array of convex or concave clear acrylic rods. This combination produces a large-scale lenticular that creates a three-dimensional depth effect. The acrylic rods are available in 10mm, 15mm and 20mm wide profiles. This development was triggered by a request from a customer who wanted a fluted glass effect. Starting with a photographic image it became apparent that adding the acrylic rods enhanced the effect and from that single project this new range has developed.

Folio has already been used on many iconic high-end retail and hospitality projects. The Fluted system adds another layer of interest to an already successful product range.

www.folio.it

Email: david@dmadesign.co.uk

Web: www.dmadesign.co.uk